100-277vac triac & 0 10v dimmable led strip driver power supply junction box for led driver

This triac & 0 10v dimmable constant voltage led power supply is integrated with the junction box and has a built-in fine-tuning voltage function knob. Metal housing design, natural air cooling.With short circuit/overload/over temperature protection, it is suitable for indoor and outdoor dimming led lighting project installation. 7 years warranty

Specification

| Model | SMT-12200-VTD-J | SMT-24200-VTD-J | SMT-36200-VTD-J | SMT-48200-VTD-J | |

| Certificate | UL / cUL / FCC / Class P | ||||

| Output | DC Voltage | 12V | 24V | 36V | 48V |

| Voltage Tolerance | ±4% | ±3% | ±3% | ±2% | |

| Voltage Regulation | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | |

| Load Regulation | ≤2% | ≤1% | ≤1% | ≤1% | |

| Rated current | 16.67A | 8.33A | 5.56A | 4.17A | |

| Rated power | 200W | ||||

| Voltage Ripple | 250mVp-p | 250mVp-p | 250mVp-p | 250mVp-p | |

| Overshoot voltage | <5%(full load) | <20%(full load) | <10%(full load) | <10%(full load) | |

| Output volt Adjustment | 12-13V | 24-26V | 36-38V | 48-50V | |

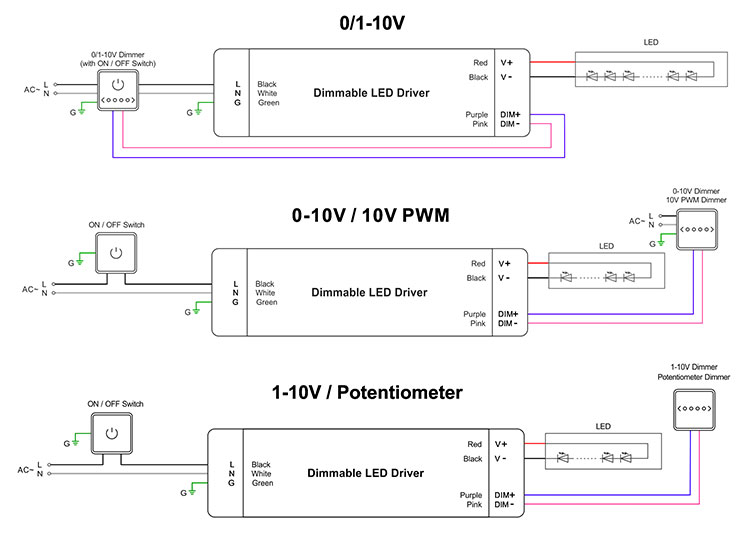

| Output mode selection | The DIP switch in the "ON" position represents the PWM (Pulse - Width Modulation) mode, and in the "1" position represents the VR (Modulation of DC Voltage) mode. | ||||

| Switching the output mode requires the power to be cut off for 3 seconds and then powered on again for the mode switching to take effect. | |||||

| Input | Voltage Range | 120-277VAC | |||

| Frequency Range | 47 - 63Hz | ||||

| Power Factor (Typ.) @ full load |

>0.98@120VAC >0.96@277VAC |

>0.98@120VAC >0.96@277VAC |

>0.98@120VAC >0.96@277VAC |

>0.98@120VAC >0.96@277VAC |

|

| THD(Typ. ) @ full load | <15%@120V <15%@277V | ||||

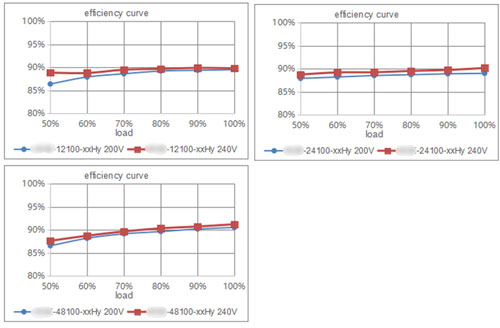

| Efficiency(Typ.) @ full load |

≥86.5%@120VAC ≥90%@277VAC |

≥89%@120VAC ≥92%@277VAC |

≥89%@120VAC ≥93%@277VAC |

≥90%@120VAC ≥92%@277VAC |

|

| AC Current (Max.) | ≤2.2A @120VAC ≤0.91A@277VAC | ||||

| Standby power | ≤0.5W | ||||

| Inrush Current (Typ.) | 40.8A, 50%, 480us @120VAC; 96.7A, 50% 192us @277VAC | ||||

| Leakage current | <0.5mA | ||||

| Protection | Short Circuit | Hiccup mode, can be automatically restored after abnormal removal | |||

| Over Load | ≥120%,Constant - Current Mode, automatic recovery after exception | ||||

| Over temperature | When the ambient temperature exceeds 55℃ ±5℃, the output is turned off | ||||

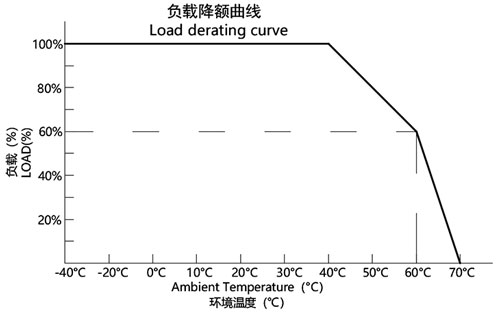

| Environment | Working TEMP. | -40~+50℃ (see below derating curve) | |||

| Working Humidity | 20 - 95%RH non-condensing | ||||

| Storage TEM.,Humidity | -40 - +80℃,10 - 95% RH non-condensing | ||||

| TEMP.coefficient | ±0.03%/℃(0 - 50℃) | ||||

| Vibration | 10 ~ 500Hz, 5G 12 minutes/cycle, X Y Z axis 72 minutes each | ||||

| Safety & EMC | Safety standards | UL8750 CAN/CSA-C22.2 No.250.13 | |||

| Withstand voltage | I/P-O/P:1.88KVac;I/P-FG::1.88KVac;O/P-FG:0.5KVac | ||||

| Isolation resistance | I/P-O/P:100MΩ / 500VDC / 25℃ / 70% RH | ||||

| Surge Immunity Test | AC Power Line:Differential Mode 2KV,Common Mode 4KV | ||||

| EMC Immunity | FCC/ICES do not request this test | ||||

| EMC Emission | FCC Part15 Subpart B;ANSI C63.4:2017;ICES-005 Issue 5 | ||||

| Others | Net Weight | 1.35KG | |||

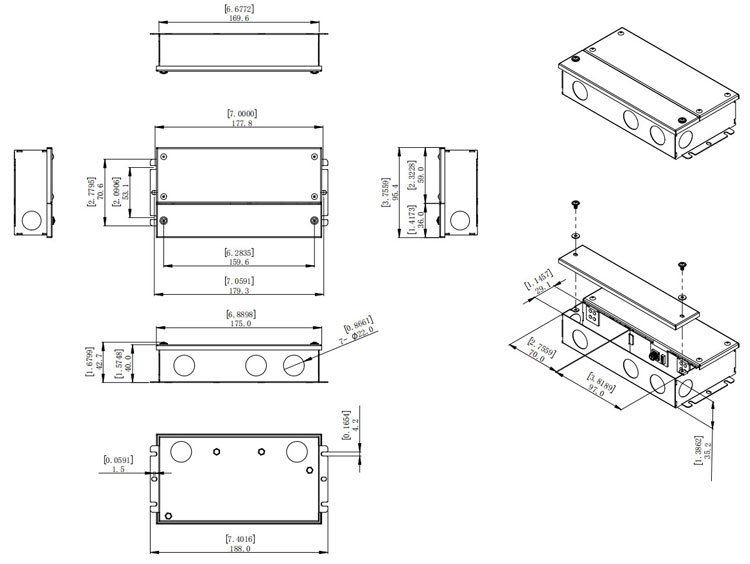

| Dimension | 205.4*118*42.7mm(L*W*H) | ||||

| Packing | 293*260*265cm 10 pcs / CTN | ||||

| Notes | 1. All parameters NOT specially mentioned are measured at 120VAC input, rated load and 25℃of ambient temperature. | ||||

| 2. Tolerance: includes set up tolerance and load regulation . | |||||

| 3. The power supply is considered as a component that will be operated in combination with final Equipment. Since EMC performance will be affected by the complete installation, the final equipment manufactures must be-qualify EMC Directive on the complete installation again. | |||||

|

4. Default states: The output mode is PWM output by default. The dimming curve is a gamma2.2 curve. |

|||||

| 5. Regarding LED driver load types where the driver meets the harmonic emissions requirements of ANSI C82.77-10. | |||||

Mechanical Specification

1. Input UL1015 0.824mm²cable 3*18AWG, Black and White to be connected to AC (L) and (N), Green to be connected to (G).

2. Output UL1015 0.824mm² cable 2*18AWG, Red (+) to LED Positive side (+), Black (-) to LED Negative side (-).

3. Please make sure you connect these correctly otherwise your product will not function correctly and could be damaged.

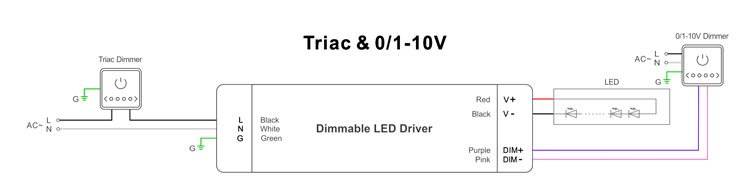

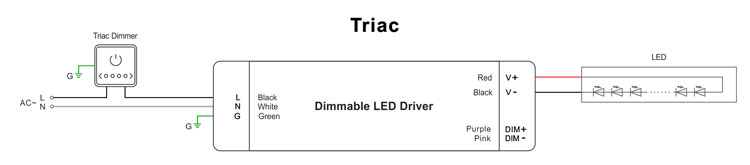

Dimming Operation

Using two ways of dimming at the same time, you must be assured that LED lighting is up to the max. Brightness then you could operate with the other dimming;

Using one dimming ---TRIAC/Phase cut dimming

1.The Pulse-Width Modulation (PWM) of output voltage can be adjusted through input terminal of the AC phase line(L) by connection

a phase /Triac dimmer or lighting system.

2.Working with Forward phase, MLV and Reverse phase, ELV, TRIAC dimmers or light system.

3.Min. loading is about 10%

4.Please try to use dimmers with power at least 2 times as the output power of the driver.

Using one dimming ---0-10/ 1-10V/ 10V PWM/ Potentiometer dimming

Derating Curve

1.To extend their life, please refer to the Derating Curve and derate according to the temperature.

2.Please note that the rise in temperature of LED fixtures over a long period of time will cause their power to rise.

Therefore, we recommend the power supply to reserve a certain amount of load to avoid overloading.

Related Products

Aluminum housing design Waterproof level ip67 triac & 0 10v dimmable led driver 200W Complies with global safety lighting regulations. UL certified with 7 year warranty

Mode:SMT-012-200VTD intput voltage:100-277vac

Size : 256*78*47MM |