DOE ETL CE Rohs 12v 72w led strip light power adapter

100-240V AC to 12V &24V DC Transformers - Driver for LED Light and Other Low Voltage Devices. ETL CE Listed. 6 to 96 watts.

Our ETL CE DOE Listed 12V 24V DC led power adapter provide the power you need to light up your LED light strips or other low voltage devices by converting your 110-240V AC power to the 12V/ 24V DC that LED strips run on. They're available in various power ratings, from 6 Watts to 96 Watts and in various styles, from compact models that plug directly into your wall outlet to larger units capable of powering several rolls of strip.

2. INPUT REQUIREMENTS for led strip light adapter:

2.1 Operating range: 90-264VAC

2.2 Rated Input Voltage :100-240VAC

2.3 Input Frequency Range: 50/60Hz +/-3Hz

2.4 Input In-rush Current: 100A max

2.5 Input Current:1.5A max

3.OUTPUT REQUIREMENTS for led light adapter:

3.1 Output Voltage and Current

|

Output |

Output Regulation(V) |

No Load |

Rating Load (A) |

|

|

Voltage(V) |

Minimum |

Maximum |

Current(A) |

Continuous Current(A) |

|

12V |

11.4V |

12.6V |

0A |

6.0A |

3.2 Output Voltage Regulation

The total output voltage regulation shall be +/-5%,including the effects of line voltage variations,load current,ripple and noise,and the AC component of the load current.

3.3 Output Voltage Ripple

The switching power supply shall not exceed the following limits in the indicated voltage for 60Hz or 50Hz ripple,switching frequency ripple and noise measured with 20MHz width.

Ripple and Noise:50/60Hz Ripple + Switching Ripple and Noise

|

Output |

Ripple |

|

0-6.0A |

200mV |

Ripple and Noise are measured at the end of output cables which are added a

0.1uF(104) Ceramic capacitor and a 22uF Electrolytic capacitor.

4. EFFICIENCY:

When 220VAC line input voltage (100-240 VAC),the efficiency shall be >82% at rating load.

5. DIELECTRIC STRENGTH (Hi-Pot) TEST:

Finished product withstands with AC3000Vrms/50Hz,5mA max,

primary to secondary, 1 minute for type test,1 second for production test.

6. INSULATION RESISTANCE:

Primary to secondary: 10MΩ min at 500VDC.

7. PROTECTION:

7.1 Short Circuit Protection

If short circuit occurs,all the output should be protected. After the fault, the adapter automatically recovers.

7.2 Over Shoot

The Output over shoot at turn-on shall not exceed 10% of normal voltage value with or without the load connected.

7.3 Start-up time

The start-up time is less than 2 second.

8.ENVIRONMENTAL CONDITIONS:

8.1 Temperature

Operating temperature: 0℃ to +40℃

Storage temperature : -20℃ to +60℃

8.2 Humidity

Relative humidity:≤95%

8.3 Operating Ambient Altitude

Altitude:0-3000m

8.4 Operating at the lower temperature

At -0℃,with the rated voltage 100-240Vac charged to the primary and unloaded and full load on the secondary 8 hours, no abnormality in electric and mechanical characteristic, after 2 hours recovery at the room temperature.

8.5 Operating at the high temperature

At +40℃,with the rated voltage 100-240Vac charged to the primary and unloaded and full Load on the secondary 8 hours, no abnormality in electric and mechanical characteristic, after 2 hours recovery at the room temperature.

9. COOLING:

Cooling shall be with natural convection cooling.

10.Burn-in

The burn-in test will be performed at least 4 hours at centigrade

degrees under full load Condition.

11.Referenced standard:

11.1 EMI Standards

Reference EN50082-1,EN55022-B,GB-17625.1-2003, GB-9254-1998

EN55013 EN55020

11.2 Safety Standards

The adapter shall be meet certified with the following safety standards.

l EN61347,GB4943-2001, J55013,J55020,J60065

12. MOUNTING CONNECTORS:

12.1 AC Input Connector

Spec :2Pin ( PIN)

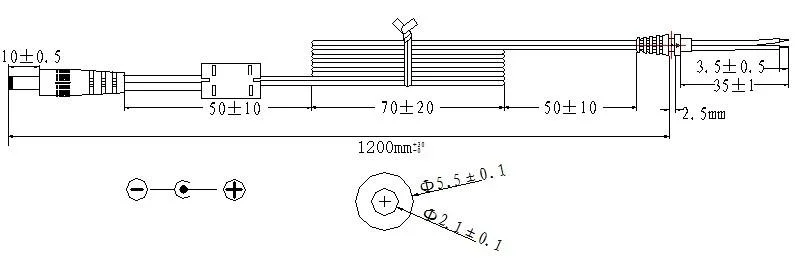

12.2 DC Output Cable

Wire : (Optional) SPT-1 18AWG*2C L=1200mm Color: Black (.)

Plug : (Optional) 5.5 x 2.1x 10mm

13. MECHANICAL FEATURES:

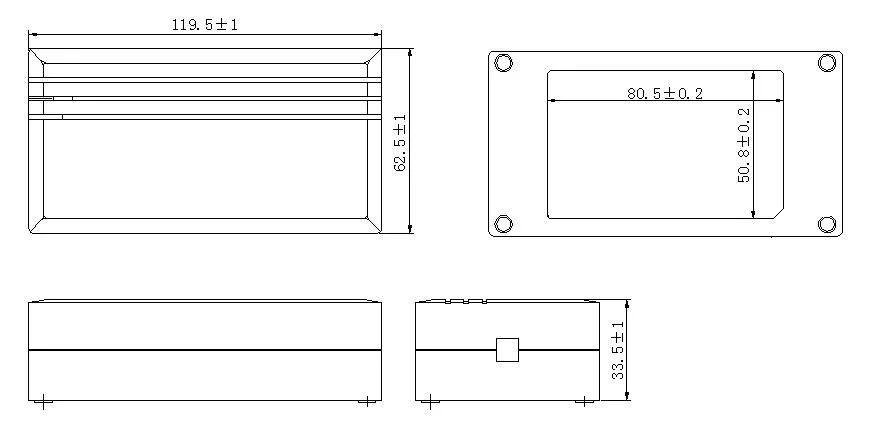

13.1 Dimension(Size)

Length: 119.5mm

Width: 62.5mm

Height: 33.5mm

13.2 Weight

The Power Supply unit : 240±10g

13.3 Vibration and shock

No Evidence of any mechanical or functional damage after the vibration and shock testing.

13.4 Drop test

After Dropping from a hight of 75 cm onto a wooden floor , Dropping at 6 sides totally, NO breakage should be happened in the test piece.

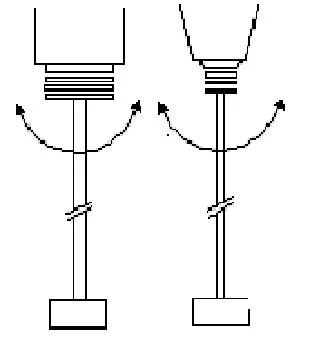

13.5 Bending Test

Fix the power supply and its plug, apply a load of 200g to the other end, turn the cable by +/-60℃ carry out this process 1000 times, at the rate of 20 times per minutes. No abnormality in mechanical and electrical Characteristic and disconnection within 30% after the test.

14 . DIAGRAM DATA:( See to attach the diagram)

14.1. APPEARANCE DRAWING:(Unit:mm)

14.2. NAME PLATE: (Unit:mm)

NOTE: MATERIAL:POLYESTER COATIONG:0.10+/-0.03mm

14.3. DIMENSION OF OUTPUT PLUG & DC CORD:(Unit:mm)