24v 96w Non dimmable constant voltage led power supply driver junction box for led strip

New upgraded Non dimmable led power supply 96W 24V/48V with built-in PFC function. Built-in fine-tuning voltage function knob. Able to compensate for light decay of lamps. UL certified, in compliance with global safety lighting regulations. 7-year warranty

Specification

| Model | SMT-24096-ND-J | SMT-48096-ND-J | |

| Certificate | UL / cUL / FCC / Class P / Type HL / Class 2 | ||

| Output | DC Voltage | 24V | 48V |

| Voltage Tolerance | ±4% | ±2% | |

| Voltage Regulation | ≤0.5% | ≤0.5% | |

| Load Regulation | ≤4% | ≤2% | |

| Rated current | 4A | 2A | |

| Rated power | 96W | ||

| Voltage Ripple | 296mVp-p | 176mVp-p | |

| Overshoot voltage | <3% (full load) <4%(no load) | ||

| Input | Voltage Range | 100-277VAC | |

| Frequency Range | 47 - 63Hz | ||

| Power Factor (Typ.) @ full load |

>0.98@120VAC >0.96@277VAC |

>0.98@120VAC >0.96@277VAC |

|

| THD(Typ. ) @ full load | <15%@120V <15%@277V | ||

| Efficiency(Typ.) @ full load |

≥88.4%@120VAC ≥92.0%@277VAC |

≥89.2%@120VAC ≥91.8%@277VAC |

|

| AC Current (Max.) | ≤1.0A @120VAC ≤0.43A@277VAC | ||

| Inrush Current (Typ.) | 51A@50%Ipeak 208us @120VAC 118A@50%Ipeak 452us @277VAC. | ||

| Leakage current | <0.5mA | ||

| Protection | Short Circuit | Hiccup mode, can be automatically restored after abnormal removal | |

| Over Load | ≥120%,Constant - Current Mode, automatic recovery after exception | ||

| Over temperature | When the ambient temperature exceeds 55℃ ±5℃, the output is turned off | ||

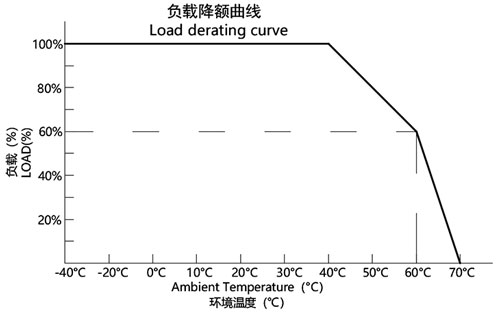

| Environment | Working TEMP. | -40~+40℃ (see below derating curve) | |

| Working Humidity | 20 - 95%RH non-condensing | ||

| Storage TEM.,Humidity | -40 ~ +80℃,10 - 95% RH non-condensing | ||

| TEMP.coefficient | ±0.03%/℃(0 - 50℃) | ||

| Vibration | 10 ~ 500Hz, 5G 12 minutes/cycle, X Y Z axis 72 minutes each | ||

| Safety & EMC | Safety standards | UL8750 CAN/CSA-C22.2 No.250.13 | |

| Withstand voltage | I/P-O/P:1.88KVac;I/P-FG::1.88KVac;O/P-FG:0.5KVac | ||

| Isolation resistance | I/P-O/P:100MΩ / 500VDC / 25℃ / 70% RH | ||

| Surge Immunity Test | AC Power Line:Differential Mode 2KV,Common Mode 4KV | ||

| EMC Immunity | FCC/ICES do not request this test | ||

| EMC Emission | FCC Part15 Subpart B;ANSI C63.4:2017;ICES-005 Issue 5 | ||

| Others | Net Weight | 1.06Kg | |

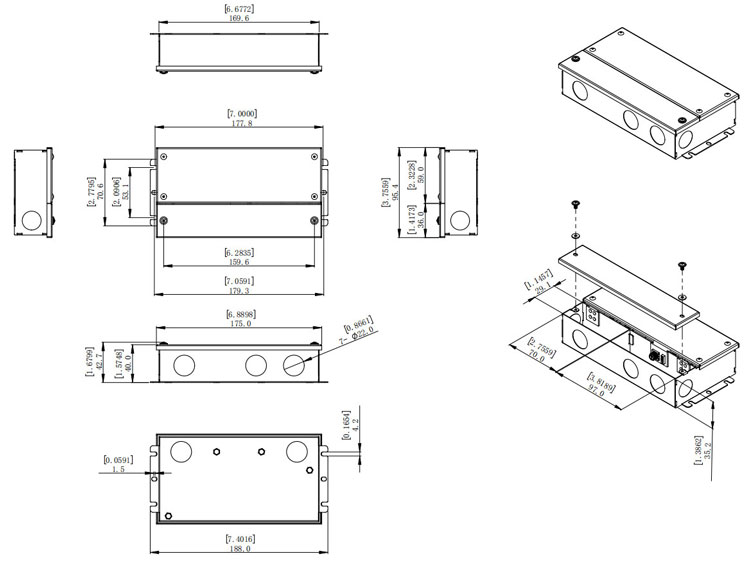

| Dimension | 188.0*95.4*42.7mm(L*W*H) | ||

| Packing | 415*265*270mm 20 pcs / CTN | ||

| Notes | 1. All parameters NOT specially mentioned are measured at 120VAC input, rated load and 25℃of ambient temperature. | ||

| 2. Tolerance: includes set up tolerance and load regulation . | |||

| 3. The power supply is considered as a component that will be operated in combination with final Equipment. Since EMC performance will be affected by the complete installation, the final equipment manufactures must be-qualify EMC Directive on the complete installation again. | |||

| 4. Regarding LED driver load types where the driver meets the harmonic emissions requirements of ANSI C82.77-10. | |||

Mechanical Specification

| American wire gauge | |

| Input wire | Black(L) White(N) Green(G) (3*18 AWG) |

| Output wire | 12V:Red(V+) Black(V-) (2*16 AWG) |

| 24V,48V:Red(V+) Black(V-) (2*18 AWG) | |

MCB recommendation

| When the input voltage is 120Vac,the number of LED Driver matched by circuit breakers is as follows: | ||

| MCB Type | Level | The number of LED Driver |

| C type | 10A | 6 |

| 13A | 7 | |

| 16A | 9 | |

| 20A | 12 | |

| 25A | 15 | |

| When the input voltage is 277Vac,the number of LED Driver matched by circuit breakers is as follows: | ||

| MCB Type | Level | The number of LED Driver |

| C type | 10A | 14 |

| 13A | 18 | |

| 16A | 22 | |

| 20A | 28 | |

| 25A | 30 | |

Note:

1. The above quantities of the led drivers connected on the Type C is recommended base on the maximum ambient temperature is 50 ℃.

2. The breaker should be selected according to the input rated voltage, input rated current, ambient temperature, and tripcharacteristic curve.

Derating Curve

1. To extend their life, please refer to the Derating Curve and derate according to the temperature.

2. Please note that the rise in temperature of LED fixtures over a long period of time will cause their power to rise.

Therefore, we recommend the power supply to reserve a certain amount of load to avoid overloading.

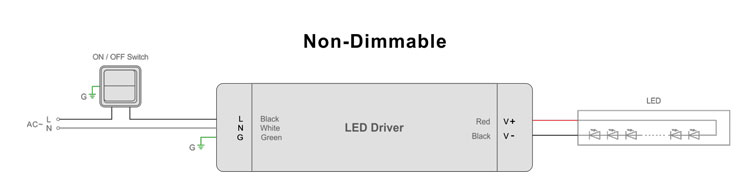

Instruction

1. Confirm if the rated input voltage of the power supply is within the range of market voltage before use.

2. Pay attention to the distinction between the input and output lines of the power supply to avoid power damage or unnecessary safety accidents caused by connecting the reverse line.

3. The power supply cannot be stacked for installation (placement), and the installation distance between the power supply and the power supply should be greater than 10cm. Multiple power supplies should be installed in a narrow space, and the environmental temperature should be less than 55 ℃ during use; For example, distribution boxes, etc.

4. In order to extend the service life of the power supply, the power supply should be installed in an environment that is conducive to heat dissipation as much as possible;

5. As the ambient temperature increases, the power used by the power supply gradually decreases, and the lifespan of the power supply also gradually shortens.

6. Do not use under abnormal loads: Overloading can cause damage to the power supply, and extremely light loads can cause the power supply to malfunction.

7. To ensure safety and reduce interference, please ensure that the grounding wire is reliably grounded

8. If the LED driver do not work normally, pl. don’t maintain privately, but contact us: sales1@smartselectronics.com Or take a phone call: 0086-595-27256889

Related Products

Aluminum housing 100W Non dimmable LED driver Constant voltage working mode. Good heat dissipation, waterproof grade ip67, can be well waterproof and dustproof. Comply with global safety lighting regulations. 7 years warranty

Mode:SMT-024-100VWN intput voltage:100-277vac

Size : 230*70*43MM |